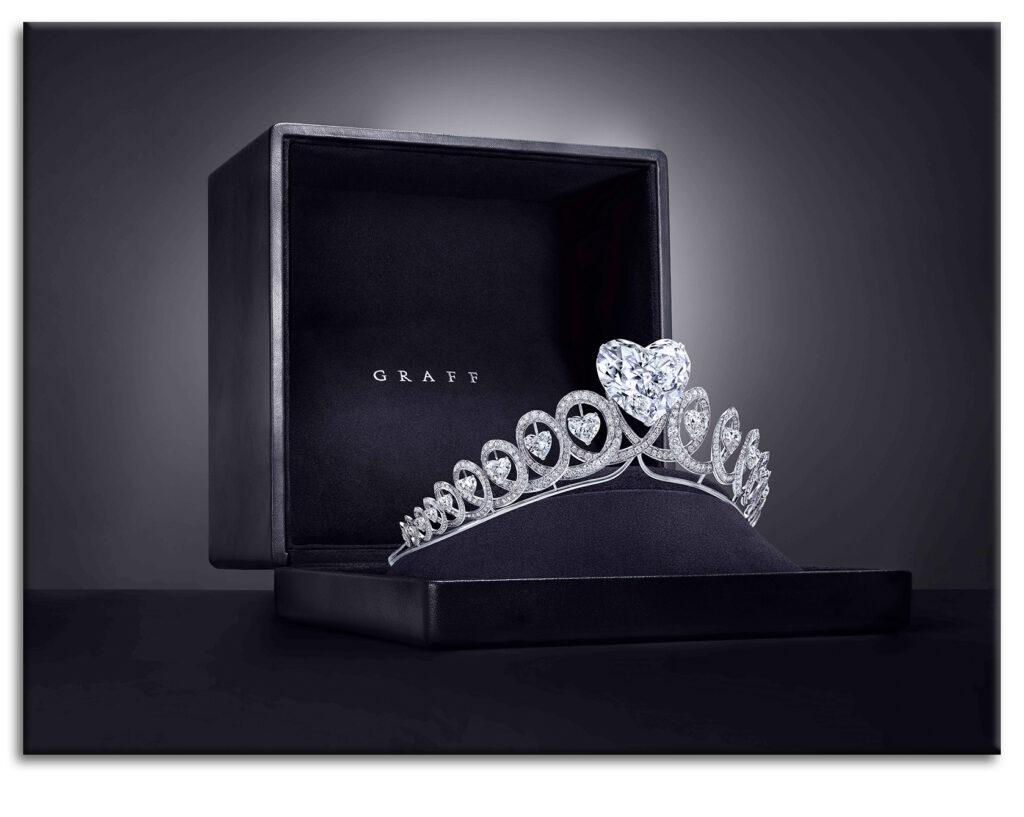

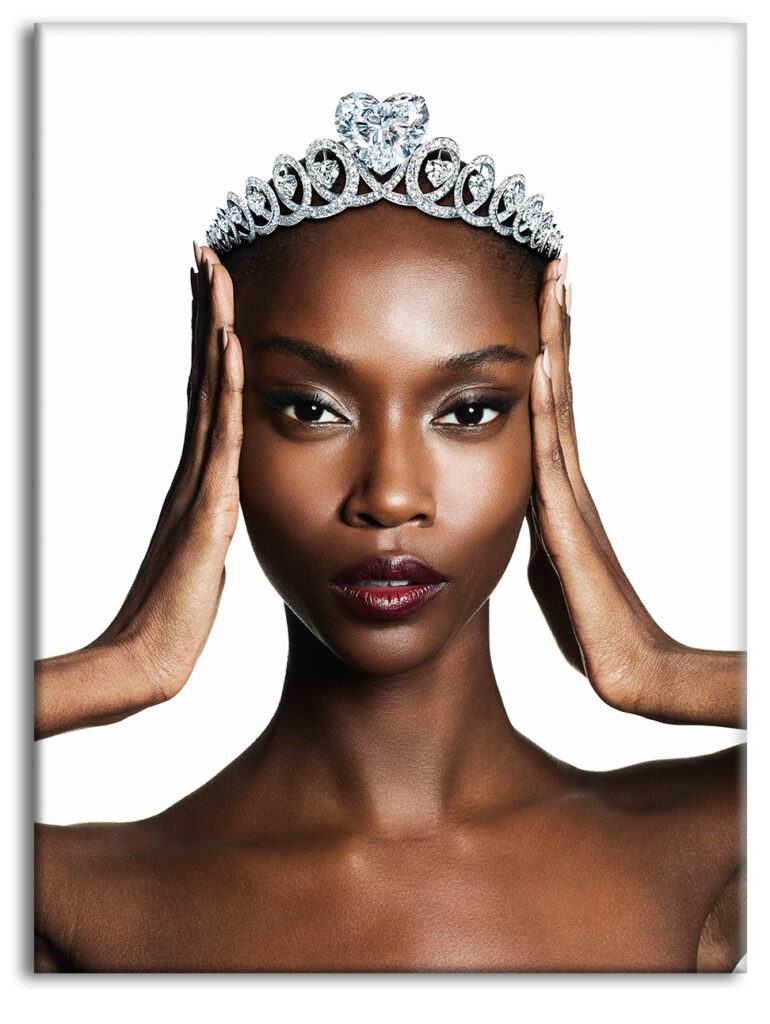

Romance & Power – the Graff Infinity Tiara

By Nina Hald & Gary Roskin

Graff Diamonds may celebrate a classic, romantic feminine expression with colorless diamonds in the Infinity tiara, unveiled on the occasion of the celebratory opening of a new Graff flagship store at the Ginza in Japan in November last year, but there is a not-so-subtle power behind the sheer size of the central diamond – the Infinity Diamond. Thanks to improved mining methods, larger diamonds have been retrieved within the past five years, yielding the potential for some absolutely fabulous gemstones, as this record-holder, the world’s largest heart-shape diamond of some 157.80 carats, is a testament to.

Discovery

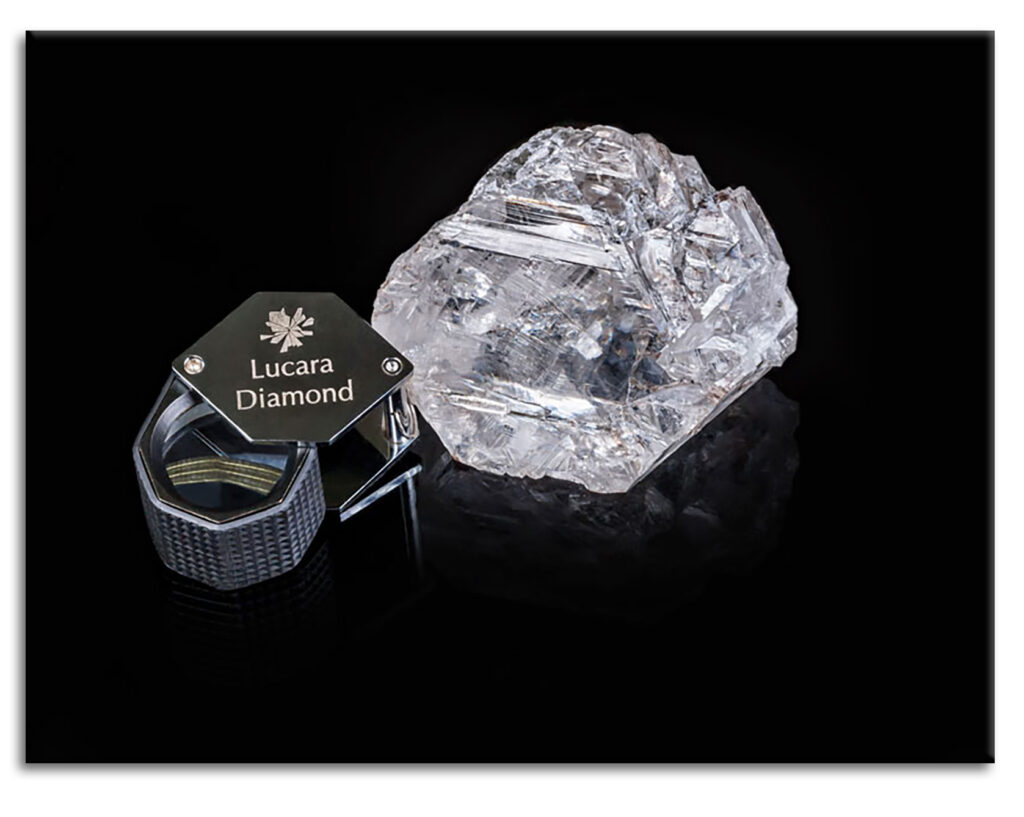

In a thrilling twist of fate, when a 373 carats diamond and the 1,109 carats Lesedi La Rona were placed side by side, their contours fit perfectly together like two pieces of a precious jigsaw puzzle, supporting the theory that they once formed part of an even larger diamond.

Determined to unite the two rough stones and ensure their history would remain forever entwined, Laurence Graff acquired the Lesedi La Rona shortly after the 373 carats diamond – both from the Karowe Mine in Botswana. Further marking the 373 carats diamond as a stone of great distinction, scientific research conducted by the Gemological Institute of America (GIA) revealed that it was part of an elite group of large and exceptionally rare diamonds that formed three times deeper in the earth’s mantle than most other diamonds.

Analysis

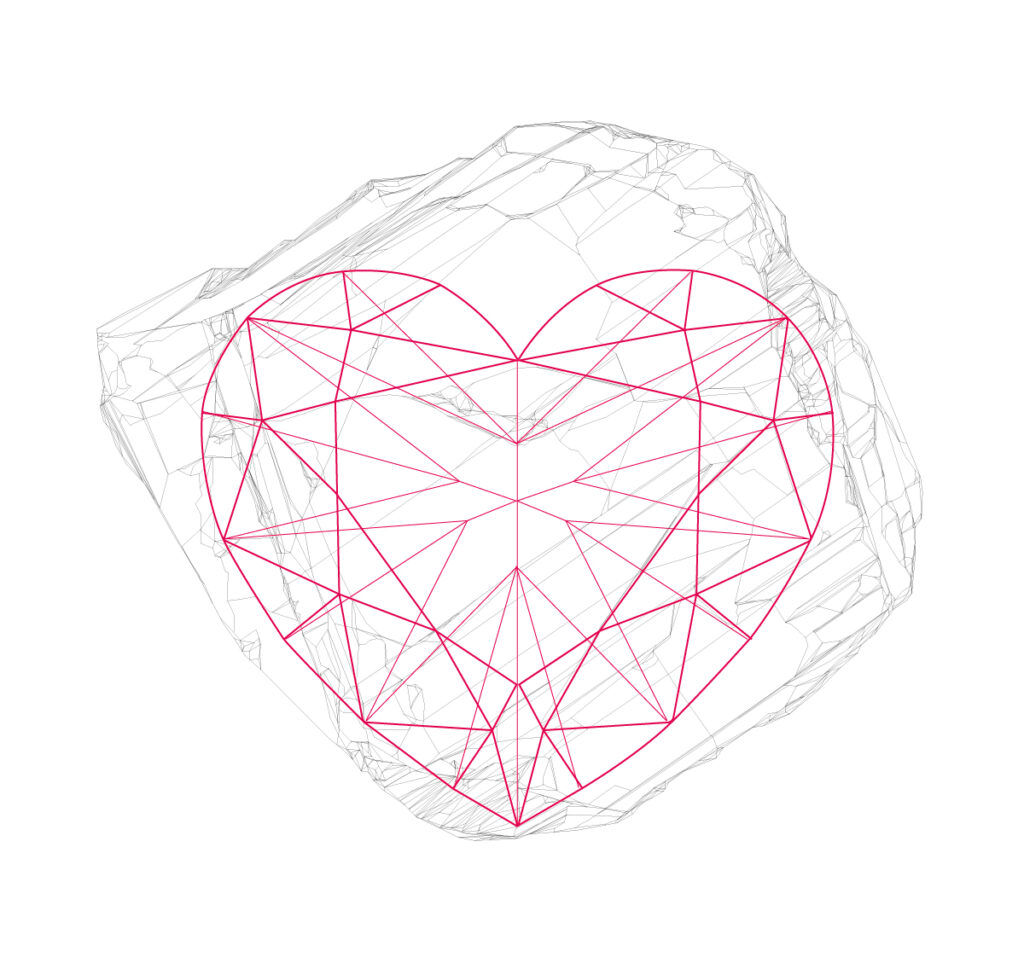

Using the latest precision scanning technology, Graff’s team of gemmologists mapped the precise inner structure of the 373 carats diamond. After weeks of scrutiny, it was revealed that hidden within was the promise of a heart shape diamond, the magnitude – a potential of more than 150 carats – of which had never been seen before. The romantic heart shape is one of Graff’s most iconic diamond cuts and a difficult one to master. The finest heart shape gems display exceptional scintillation and absolute symmetry, and it would require the extreme skill of a master cutter with more than 40 years of experience to transform the 373 carats diamond into a perfect heart shape – a challenge made even more daunting due to the sheer size of the rough stone. After creating an approximate outline of the heart shape, the master cutter spent many months finessing the polished diamond until it was completely symmetrical, with an aesthetically beautiful cleft, impeccably sharp point and flawless facets angled to optimize the fire and light that danced within. A painstakingly slow and steady process, it took six weeks alone to refine the diamond’s delicate cleft.

Quality Grading

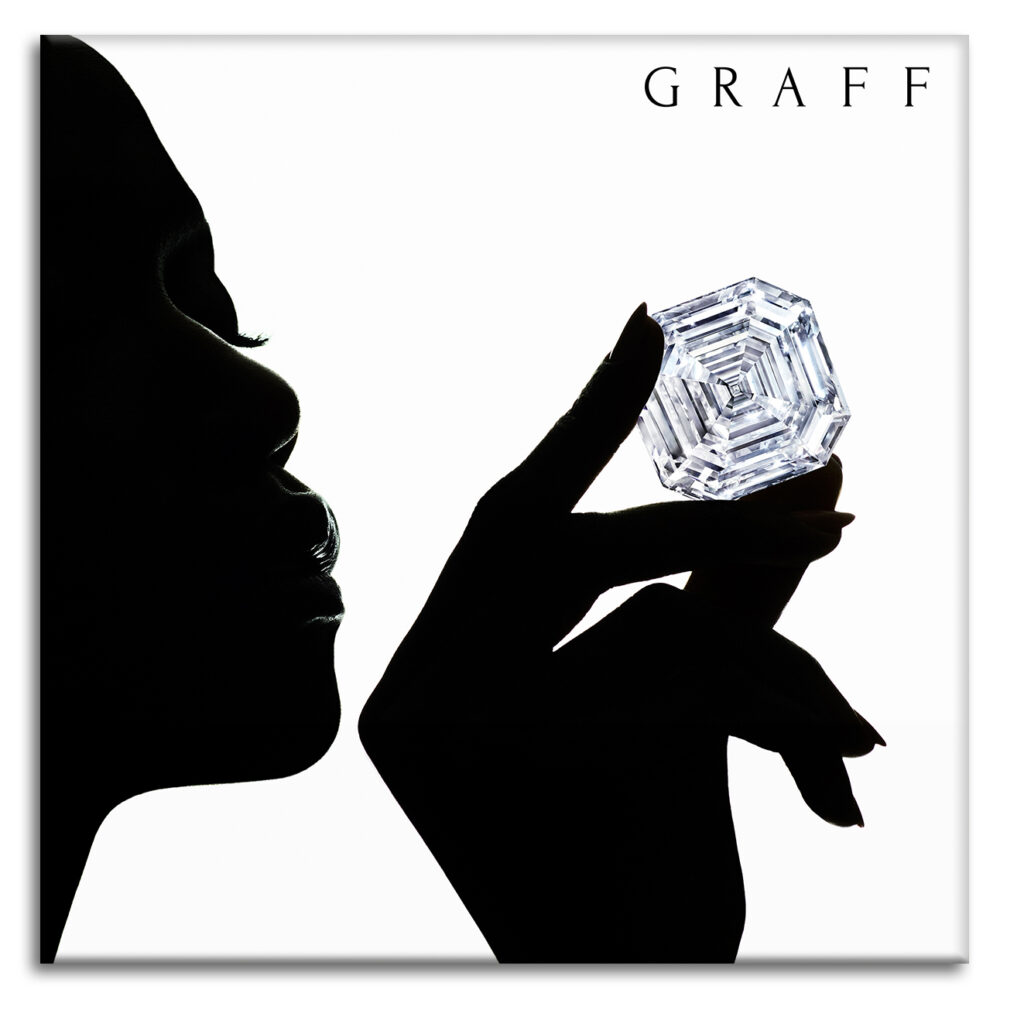

After more than a year of undivided expert attention, the finished Infinity diamonds has been revealed as a triumph of diamond mastery. The heart shape stone was then sent to the GIA for quality analysis, and within weeks, the news Graff had been eagerly awaiting was confirmed. The 157.80 carat heart shape diamond – graded by the GIA as a D color and VVS1 clarity – is officially the largest heart shaped diamond in the world. To celebrate the resounding success, the heart shape diamond was named The Infinity, in honor of the Graff family’s infinite love of diamonds. Commenting, Laurence Graff said: “The Infinity represents not only the finest diamond craftsmanship but also my family’s passion for hunting out the most exceptional stones in the world. I have devoted my life to diamonds, and the Infinity is a true masterpiece. When holding it in your hand, it is impossible not to be moved by its majesty. The fact that it was once part of the historic Lesedi La Rona only serves to reinforce its uniqueness.”

Design

After more than a year’s work, the diamond was ready to be set. Anne Eva Geffroy, Graff’s Design Director, had just one creation in mind as soon as she set eyes upon The Infinity. Taking inspiration from the heart shape stone’s opulent curves, it had to be a jewel of exquisite grandeur – a tiara. The bespoke mount was uniquely created for the incomparable diamond, and accompanied by 18 heart shape diamonds, suspended within the looping swirls, upon its completion, this majestic jewel was named the Infinity Tiara. A masterpiece of design and diamond craftsmanship, the tiara’s fluid and sculptural lines are naturally arranged to compel the eye towards the luminous beauty of the Infinity Diamond.

Legacy

Throughout the company’s rich history, Graff has dominated the list of historical and important rough diamonds discovered, cut and polished this century. Some of those exceptional diamonds include the 302.37 carat Graff Lesedi La Rona, the largest highest color, highest clarity diamond ever graded by the GIA and the world’s largest square emerald cut diamond, The Graff Venus, The Lesotho Promise, The Delaire Sunrise, The Wittelsbach-Graff, The Graff Perfection, The Graff Pink and The Golden Empress – and now, the Infinity Diamond has joined that roster.

Mining for Large Diamonds

In all mining operations, the goal is to have 100% recovery of the product you are seeking. In this regard, diamond mining is no different than any other mining operation. However, because of the high value of the end product, greater recovery makes an enormous difference in the profitability of the mine. Finding large diamonds of 10, 20, and 30 carats and more, can certainly increase a diamond mine’s profit margin substantially. And if in the process you can recover very large important diamonds, of 100, 200, 300 carats and larger, well, history can be made.

Tomra and Bourevestnik

There are two diamond recovery sorting manufacturers that appear to be leading the industry. Tomra, of Asker, Norway, and Bourevestnik, of St. Petersburg, Russia. Both Tomra and Bourevestnik utilize what’s called XRT technology, aka X-ray Transmission. Basically, XRT is used to find dense material that does not transmit (absorb) X-Rays. Diamond is one of those dense materials and does not transmit (absorb) X-rays easily.

The idea of using X-rays to find diamond is not new. The use of X-ray fluorescence (XRF), and X-ray luminescence (XRL), is still being utilized. But today, the level of sophistication has advanced greatly. What we are seeing now with this new technology is the use of different levels of X-ray, combined with with near infrared (NIR), and possibly even LASER to find every diamond in the concentrate. This includes those large important Type IIa diamonds that are troublesome to detect. Along with better crushing strategies, allowing for larger ore, up to 250 mm in size, and using XRT on the larger pre-concentrate gravels, mines can now locate the larger diamond crystals before having been transported off to be crushed into smaller ore sizes.

Samples yield BIG stones

Bourevestnik, with hundreds of sorters throughout the world, including notable mines such as the Cullinan, the Finsch, and the Letseng mines in the Republic of South Africa, and the Williamson in Tanzania, had proven their technology by recovering some very large rough diamonds (40 carat +) from tailings at the Letseng mine. Tomra proved their worth in the first two weeks of operation at Lucara’s Karowe Mine in Botswana by finding the second largest gem quality diamond ever found, the 1,109 carat Lesedi La Rona (meaning “Our Light” in the local Tswana language).

Tomra Diamond sensor-based recovery systems, created a proprietary system that, depending on the model, uses dual x-ray, density, and near infrared to identify and recover close to 100% of the mine run, including the more difficult to spot Type IIa diamonds. As they say on their website, “in diamond sorting, every rock counts.” Using sorting and recovery machines that examine up to 250 mm particle size to capture the larger rough crystals, these machines have really upped the diamond recovery process, giving us historically important finds.

Lucara and the Karowe Mine

Lucara Diamond Corp, established in 2012, acquired AK6, now the Karowe Diamond Mine. Eira Thomas, CEO of Lucara notes that Karowe is extremely important for large Type IIa diamonds. After their initial review of previous sampling, their first concern was in increasing recovery and minimizing breakage. They knew from those earlier test results that the mine had the potential for high concentrations of important stones; Type IIa diamonds that contain little to no nitrogen, nitrogen being the main cause for yellow color. Type IIa diamonds are typically very clean, colorless, and can be quite large.

Prior recovery technology was limited, but they now felt that the mine could produce better yields, especially noting that larger crystals could be spared using better technology. “Using modern mining methods, we could minimize the damage,” says Thomas. They call that “diamond value preservation.” In 2015, Lucara invested $30-35 million dollars in Tomra’s technology, and it has paid off.

John Armstrong, Vice President, Technical Services at Lucara Diamond Corp. explains that, “with the early record-breaking diamond recoveries, we were able to demonstrate to the world that we can recover large high-quality gemstones.”

Armstrong elaborated. “In November of 2015, … in a very short period of time, we recovered an 813 carat stone, and the 1,109 carat Lesedi La Rona, the second largest gem quality diamond ever to be recovered, and the largest gem quality diamond to be held in someone’s hands in over a hundred years.”

This new diamond recovery system has been an historic game changer, and, if you don’t mind us saying, it is at the heart of the Graff Infinity Tiara.